Refurbishing Diesel Generators A Comprehensive Guide to Extending the Lifespan and Efficiency of Your Power Source

Introduction

Diesel generators are a vital component of many industries and facilities, providing backup power during outages and serving as the primary source of electricity in remote locations. Over time, these generators may experience wear and tear, leading to decreased performance and efficiency. Refurbishing diesel generators can help extend their lifespan and improve their reliability, ultimately saving time and money for businesses and organizations. In this article, we will explore the importance of refurbishing diesel generators, the benefits of doing so, and the step-by-step process of refurbishing these essential power sources.

Importance of Refurbishing Diesel Generators

Diesel generators are known for their durability and reliability, but like any mechanical equipment, they require regular maintenance to ensure optimal performance. Refurbishing diesel generators is crucial for several reasons:

1. Extend Lifespan: By refurbishing a diesel generator, you can address any issues or wear and tear that may be affecting its performance. This can help extend the lifespan of the generator and prevent costly breakdowns in the future.

2. Improve Efficiency: Over time, diesel generators may become less efficient due to factors such as dirty fuel filters, worn-out parts, or outdated technology. Refurbishing the generator can help improve its efficiency, leading to lower fuel consumption and reduced operating costs.

3. Ensure Reliability: When it comes to backup power sources, reliability is key. Refurbishing a diesel generator can help ensure that it will perform as expected during power outages or emergencies, providing peace of mind to businesses and organizations that rely on uninterrupted power supply.

4. Cost-Effective Solution: Refurbishing a diesel generator is often more cost-effective than replacing it with a new unit. By addressing issues and upgrading components through refurbishment, you can save money in the long run while still benefiting from a reliable power source.

Benefits of Refurbishing Diesel Generators

Refurbishing diesel generators offers a wide range of benefits to businesses and organizations that rely on these power sources. Some of the key advantages include:

1. Increased Reliability: Refurbishing a diesel generator can significantly improve its reliability, ensuring that it will perform when needed most. This is especially important for critical facilities such as hospitals, data centers, and manufacturing plants.

2. Improved Performance: Refurbishing a diesel generator can help enhance its performance by replacing worn-out parts, upgrading components, and addressing any underlying issues. This can lead to better fuel efficiency, reduced emissions, and overall improved operation.

3. Cost Savings: Refurbishing a diesel generator is often more cost-effective than purchasing a new unit. By extending the lifespan of your existing generator through refurbishment, you can save money on capital expenditures while still benefiting from a reliable power source.

4. Environmental Benefits: Refurbishing diesel generators can also have environmental benefits by reducing emissions and improving fuel efficiency. By ensuring that your generator operates at peak performance, you can minimize its impact on the environment and comply with regulations.

5. Customization Options: When refurbishing a diesel generator, you have the opportunity to customize it to better suit your specific needs and requirements. Whether you need additional power output, enhanced control features, or improved monitoring capabilities, refurbishment allows you to tailor your generator to meet your unique demands.

Step-by-Step Process of Refurbishing Diesel Generators

Refurbishing a diesel generator involves a series of steps to identify issues, address maintenance needs, and upgrade components to improve performance. The following is a step-by-step guide to refurbishing a diesel generator:

1. Initial Assessment: The first step in refurbishing a diesel generator is to conduct a thorough assessment of the unit. This includes inspecting the generator for any visible signs of wear and tear, checking fluid levels, and testing the electrical components for proper functionality.

2. Identify Issues: Once the initial assessment is complete, identify any issues or problems that need to be addressed during the refurbishment process. This may include worn-out parts, outdated technology, or performance inefficiencies.

3. Develop a Refurbishment Plan: Based on the assessment and identified issues, develop a refurbishment plan that outlines the necessary repairs, upgrades, and maintenance tasks to be performed on the diesel generator. This plan should include a timeline, budget, and list of required parts and materials.

4. Disassembly and Cleaning: Before refurbishment can begin, disassemble the diesel generator and thoroughly clean all components to remove dirt, debris, and contaminants. This will help improve the efficiency and performance of the generator once it is reassembled.

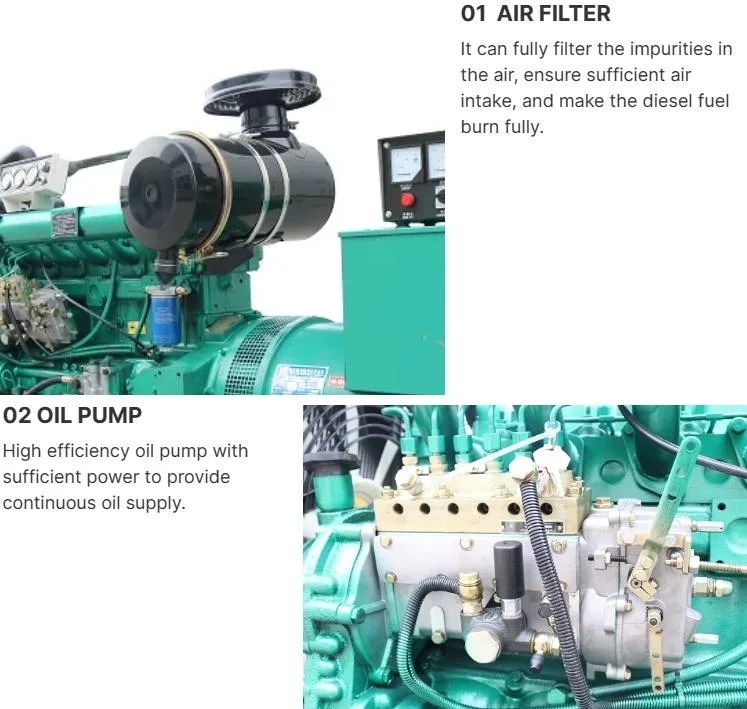

5. Replace Worn-Out Parts: During the refurbishment process, replace any worn-out or damaged parts with new, high-quality components. 200kw diesel generator for construction equipment may include filters, belts, hoses, gaskets, and other components that are essential for the operation of the generator.

6. Upgrade Technology: To improve the performance and efficiency of the diesel generator, consider upgrading its technology and components. This may include installing a new control panel, updating the engine management system, or integrating remote monitoring capabilities for better control and oversight.

7. Test and Calibration: Once all repairs and upgrades are complete, test the diesel generator to ensure that it is functioning properly. Calibration may be necessary to adjust settings and parameters for optimal performance and efficiency.

8. Reassembly and Final Inspection: Reassemble the diesel generator and conduct a final inspection to verify that all components are properly installed and functioning as intended. This includes checking for leaks, testing electrical connections, and ensuring that safety features are operational.

9. Performance Testing: Before putting the diesel generator back into service, perform performance testing to verify that it meets the required power output, efficiency, and reliability standards. This may involve load testing, voltage regulation tests, and other performance checks.

10. Maintenance and Monitoring: After refurbishing the diesel generator, establish a regular maintenance schedule to keep the unit in optimal condition. Monitor its performance, fuel consumption, and emissions to identify any potential issues and address them proactively.

Conclusion

Refurbishing diesel generators is a cost-effective and efficient way to extend the lifespan, improve the performance, and ensure the reliability of these essential power sources. By following a step-by-step process that includes assessment, identification of issues, repairs, upgrades, and testing, businesses and organizations can refurbish their diesel generators with confidence. The benefits of refurbishing diesel generators extend beyond cost savings to include increased reliability, improved performance, and environmental benefits. By investing in the refurbishment of diesel generators, businesses can continue to rely on these critical power sources for years to come.